In a world where people are more and more concerned with economic and ecological impact it’s no surprise that underlay is making a comeback.

Having spent some years in the doldrums as a drab, old-fashioned alternative to space-age, modern foam-backed carpets, is traditional underlay on the way back?

The coming of plastic carpet

Foam-backed carpet gained sway in the Sixties and Seventies as the general drive toward plastic-based materials was seen as a technological advance and therefore desirable.

More vibrant, psychedelic colours and patterns can be produced very easily with materials like nylon, polypropylene and polyester and they are also hard-wearing and the colours don’t fade.

This was also part of a shift towards the modern look of fitted carpets, covering the whole floor from wall-to-wall, rather than the traditional approach of square carpets with an uncarpeted border around the edge.

Although having a fitted carpet is possible with natural materials like wool and hessian-backed carpets, it is considerably more expensive.

Plastic foam-backed carpets are cheaper to manufacture and certainly easier to lay than traditional woven or hessian-backed carpets, which absolutely must have separate underlay.

This increases carpet laying time by at least half as much again, as you have to cut and lay twice as much material. It’s nowhere near double the time though, as underlay doesn’t have to be cut with the same accuracy as the fitted carpet layer on top.

Comeback of underlay

The increasing interest in carpet with underlay comes from a backlash against man-made materials and a change in flooring style.

More natural products are being preferred in the home as we become more ecological aware and concerns about toxins from plastics in the environment take hold.

Of course not all underlay is necessarily ecologically sound, although there are two aspects to this. The first is the ecological impact of the manufacture and life of the underlay itself and the second is the affect of underlay’s insulating properties on energy consumption in the home.

Underlay for laminate flooring

It’s that second consideration that’s prompted the revival of underlay and, to be honest, it’s nothing to do with carpet. The surge in popularity of wood and wood-effect laminate flooring, fuelled by property programmes on TV, has generated a new market for underlay although it’s very different to the felt or rubber underlay of old.

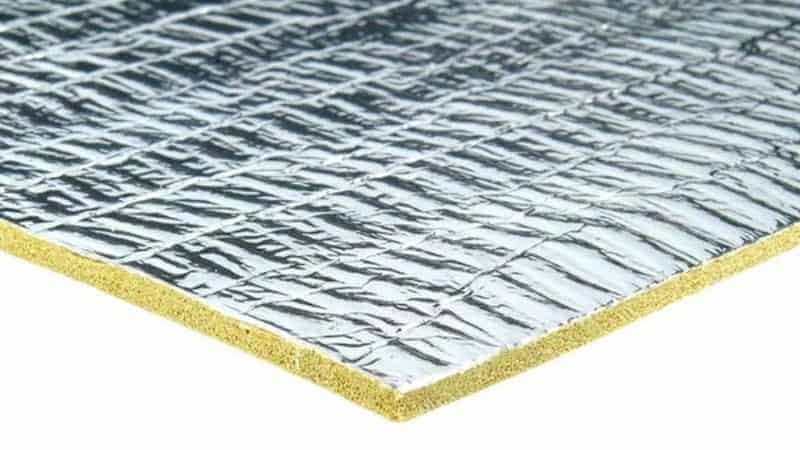

Laminate flooring needs underlay for three reasons, for thermal insulation, sound deadening but mainly to allow the flooring to ‘float’ slightly, because it expands and contracts with fluctuations in temperature and moisture. The underlay found under laminate flooring isn’t at all natural though. It is nearly always two sheets of plastic with a different plastic in between, sometimes polystyrene beads, and as such has a very bad ecological footprint.

Other variations are becoming available now though. Wool underlay that can be used under laminate flooring can now be found and has excellent sound insulation properties.

The same is true of wood fibre, which comes in boards rather than rolls, but there aren’t any felt variants available yet for laminate flooring.

Be warned that not all the natural underlays for laminate flooring will work with underfloor heating, so check before you lay.

Carpet and underlay

Choosing underlay for use under carpet is simpler as most underlays can be used. It is essential to have underlay beneath wool, woven and hessian-backed carpets otherwise the will wear very quickly.

Felt-backed carpets obviously have the felt as a built-in underlay layer, but that layer often isn’t very thick and an extra layer of felt underlay will make the carpet feel softer, warmer and will have better sound insulation.

Alternatives to felt include PU foam which is made from recycled sofas and rubber, which is completely natural. If you are using foam-backed carpet you must not use any extra underlay, although a layer of brown paper or newspaper laid on the floor will prevent it from sticking over time.

Underlay Options

Laying it down

As to laying underlay, whether it’s on a roll or boards, it usually doesn’t need any fixing and finishing is easy.

With both laminate flooring and carpet the underlay can be cut slightly smaller, probably half an inch to an inch, so simply cut it to fit the room with a border all the way round and then get on with the flooring layer.

Whether you are laying carpet or laminate flooring it’s clear that underlay can enhance the comfort and thermal efficiency of flooring.

Once you’ve decided which flooring to go for, see whether underlay is needed or preferred, then buy the best your budget can afford.